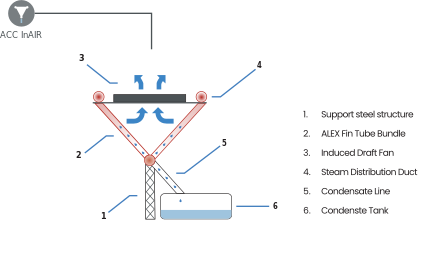

THE NEW INDUCED DRAFT AIR COOLING CONDENSER

INAIR - THE INNOVATIVE AND INTELLIGENT AIR COOLED CONDENSER SYSTEM

From the company who invented the Air Cooled Condenser, comes the next generation of innovative and intelligent design.

The InAIR combines proven components and technologies to yield the next generation in dry cooling: an Air Cooled Condenser featuring induced draft fans. Induced draft fans have been used reliably in the majority of power plant main cooling systems worldwide, like in wet cooling tower applications. Now, through innovative engineering and utilization of our self-supporting ALEX bundles, ENEXIO can offer the InAIR, an Air Cooled Condenser which offers the superior operational performance.

PRIMARY BENEFITS WITH INDUCED DRAFT FANS:

- Reduced air inlet and total height of ACC: less visual impact

- Smaller footprint of columns

- Reduction of steel structure quantities (up to -60%)

- Reduction of steel structure weight (up to -50%)

- Reduced costs for construction (-10% to -25%)

- Reduced construction duration: 20% to 30% decrease in man-hours for erection work

- Easier pre-assembly at grad

Inherent design of supporting steel structure greatly reduces the requirement of scaffolding

Reduction in the length of the main steam duct

Reduced investement costs

Shorter delivery and erection periods.

PRIMARY BENEFITS WITH INDUCED DRAFT FANS:

- Reduced air inlet and total height of ACC: less visual impact

- Smaller footprint of columns

- Reduction of steel structure quantities (up to -60%)

- Reduction of steel structure weight (up to -50%)

- Reduced costs for construction (-10% to -25%)

- Reduced construction duration: 20% to 30% decrease in man-hours for erection work

- Easier pre-assembly at grad

Inherent design of supporting steel structure greatly reduces the requirement of scaffolding

Reduction in the length of the main steam duct

Reduced investement costs

Shorter delivery and erection periods.

NO FAN BRIDGE NEEDED

In a classic forced draft Air Cooled Condenser, the fans are exposed to an elevated level of dynamic loading. The vibrational effect of dynamic loading can be mitigated by calculation and design – but not eliminated. The InAIR Air Cooled Condenser resolves this weakness in the Classic ACC design.

OPERATIONAL ADVANTAGES

- InAIR requires no fan bridge, resulting in less vibration stress which leads to longer lifetime of rotating equipment

- Minimized air recirculation due to high exit velocities of air

- Less sensivity to wind effects