AIR COOLED CONDENSERS

ENEXIO IS THE INVENTOR OF THE AIR COOLED CONDENSER

ENEXIO – as the inventor of the Air Cooled Condenser – has played a leading role in the evolution of this dry cooling technology. We are known for our comprehensive expertise in the field of cooling technology for the power generating industry and we offer the whole range of services for dry cooling systems.

In 1935, Otto Happel, in co-operation with the engineer Dr. Kurt Lang, began developing Air Cooled Condensers for stationary steam turbines. The start-up of the first ACC serving a steam turbine at the Prosper mine in Essen, Germany was in 1939.

A PROUD PART OF OUR HERITAGE IS BEING THE EXPERTS FOR AIR COOLED CONDENSERS

For us at ENEXIO, integrity means acting in accordance with our values – excellence, responsibility, integrity, passion, and diversity – wherever we do business. A key element of integrity is compliance: adherence to the law and to our own internal regulations. We have zero tolerance for corruption and violations of the principles of fair competition – and where these do occur, we respond rigorously.

The leading market position of ENEXIO in the field of power plant cooling is partly due to its expertise in both cooling processes: Wet Cooling Towers and Dry Cooling Solutions. It is a well-known fact that experience pays off. For decades, ENEXIO has been building cooling systems all over the world, covering everything – from the construction of new systems to the enhancement, maintenance and optimisation of existing systems – always to the highest quality standards and incorporating the latest findings from its own research and development programmes.

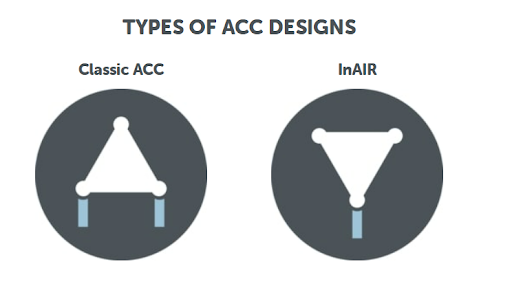

CLASSIC AIR COOLED CONDENSERS (ACC)

ENEXIO DEVELOPS SUSTAINABLE COOLING SYSTEMS TO PRESERVE NATURAL RESOURCES

A proud part of our heritage of innovation in cooling technology is in being the inventor of the Air Cooled Condenser (ACC). The ENEXIO Air Cooled Condenser is a direct dry cooling system wherein steam is condensed inside fin tubes.

Typically, the aluminum-plated fin tubes are single-row condensing tubes that are brazed with aluminum fins and are air cooled. Since they are air cooled, no water is required for main cooling of the power plant.

THE NEW INDUCED DRAFT AIR COOLING CONDENSER

INAIR - THE INNOVATIVE AND INTELLIGENT AIR COOLED CONDENSER SYSTEM

From the company who invented the Air Cooled Condenser, comes the next generation of innovative and intelligent design.

The InAIR combines proven components and technologies to yield the next generation in dry cooling: an Air Cooled Condenser featuring induced draft fans. Induced draft fans have been used reliably in the majority of power plant main cooling systems worldwide, like in wet cooling tower applications. Now, through innovative engineering and utilization of our self-supporting ALEX bundles, ENEXIO can offer the InAIR, an Air Cooled Condenser which offers the superior operational performance.

PRIMARY BENEFITS WITH INDUCED DRAFT FANS:

- Reduced air inlet and total height of ACC: less visual impact

- Smaller footprint of columns

- Reduction of steel structure quantities (up to -60%)

- Reduction of steel structure weight (up to -50%)

- Reduced costs for construction (-10% to -25%)

- Reduced construction duration: 20% to 30% decrease in man-hours for erection work

- Easier pre-assembly at grad

Inherent design of supporting steel structure greatly reduces the requirement of scaffolding

Reduction in the length of the main steam duct

Reduced investement costs

Shorter delivery and erection periods.

NO FAN BRIDGE NEEDED

In a classic forced draft Air Cooled Condenser, the fans are exposed to an elevated level of dynamic loading. The vibrational effect of dynamic loading can be mitigated by calculation and design – but not eliminated. The InAIR Air Cooled Condenser resolves this weakness in the Classic ACC design.

OPERATIONAL ADVANTAGES

- InAIR requires no fan bridge, resulting in less vibration stress which leads to longer lifetime of rotating equipment

- Minimized air recirculation due to high exit velocities of air

- Less sensivity to wind effects

ALEX-SYSTEM: ALUMINIUM FINNED STEEL TUBE SYSTEM

PATENTED SELF-SUPPORTING FINNED TUBE BUNDLE

The ALEX system of ENEXIO consists of an aluminium coated steel flat duct. Aluminium finnings between the flat ducts are hard-soldered to the aluminium coating of the flat duct. The solder fills the gap between the fin root and the core tube completely to achieve excellent heat transfer properties.

Conventional fin tube bundles need A-supports to carry the weight of tube bundles but the patented ENEXIO self-supporting fin tube bundle with integrated headers needs no support: There are only separation walls and hoist beams needed which results in material savings and a very low erection time.

- Own Heat Exchanger bundle production

- Bundle preassembly at ground level

- Only one small crane needed (1 big lift = 2 bundles)

Manual hand welding

- No guarantee of continuously welding

quality can insured. - Higher risk of manual welding defects

Robot welding

- Robot welding meets always same quality standards

- Less welding defects with robot.

- Increased productivity in tube-to-sheet welding

ALEX Single row tube design with aluminium finned flat shaped tubes

PATENTED SELF-SUPPORTING FINNED TUBE BUNDLE

- The Construction of the tube bundle for heat rejection, forms the heart and mind of Air Cooled Condenser design

- Critical manufacturing process creating the metallurgical bonding of aluminium fins to large cross section of flat steel tubes is achieved by critical brazing process technology

- The brazing process assures high strength and corrosion resistance with assurance of 100% bonding through the lifetime

- The fin geometry and design is optimized using finite element analysis and extensive thermal performance measurement

- The performance of single row condenser is thus achieved for maximum heat transfer efficiency and minimum fan power consumption

- The fins compactness and sturdiness ensure structural integrity while ensuring superior thermal performance

- The parallel and plane nature of fin tube construction uniquely ensures low fouling and time spans between cleaning cycles can be longer than with other conventional single-row designs

- Due to its high strength fin design and unlike other single row tubes bundles, the ENEXIO ALEX Tube Bundle can be cleaned with pressure water jet, achieving very thorough cleaning with reduced cleaning water consumption.

PHYSICAL CHARACTERISTICS

- Flat shaped steel with aluminium cladding

- Meandering form of aluminium

- Connection by brazing

- Single tube row design

- Tube ends welded to tube sheets

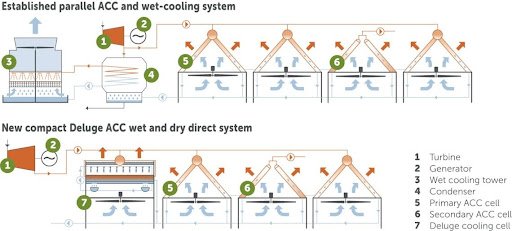

AIR COOLED CONDENSER WITH DELUGE COOLING

NEW HYBRID COOLING TECHNOLOGY – AIR COOLED CONDENSER WITH DELUGE COOLING

The Deluge Air cooled condenser is the latest technological achievement in hybrid cooling, where the primary interest is in dry cooling, but where limited water resources are available for use during certain periods of the year.

ENEXIO is one of the leading consortium partners of the EU-funded Horizon 2020 Research and Innovation programme called “MinWaterCSP” with the aim to develop advanced cooling technologies as well as integrated water management plans to reduce cooling system water consumption by up to 95% relative to wet only cooling systems.

Construction advantage

In comparison to the existing hybrid condensing systems, the Deluge Air Cooled Condenser eliminates the use of the separate wet-cooling towers, surface condenser and large cooling water recirculating piping and pumps, minimizing investment costs and plot area

Operational advantage

Turbine backpressure and associated generator output can be maintained during peak ambient temperatures and under other adverse ambient conditions such as strong winds and hot air recirculation.

The increase in scarcity of water resources worldwide is one of the main drivers towards the use of dry-cooling (cooling with air) for power plant cooling purposes instead of the more conventional wet-cooling (cooling with water) approach. However, even though dry-cooling methods allow an order of magnitude reduction in cooling water consumption, the overall power cycle efficiency is generally lower compared to cases where wet-cooling is implemented.

SIGNIFICANT LOWER CAPEX COMPARED TO CONVENTIONAL PAC-SYSTEM

The integrated hybrid cooling system consists of traditional dry air cooled condenser fan cells and a small number of wet cells, where steam is condensed inside tube bundles through external deluge cooling.